From Power Line to Innovation: How You Can Help Shape the Energy Transition

What we take for granted today was still a milestone just a few decades ago. The next chance to make history? It’s called SPARX – Safe Powerline Access & Remote eXchange.

1831 – Michael Faraday discovers electromagnetic induction.

1882 – In Berlin, electricity flows through a public grid for the first time.

1954 – Mobile cranes accelerate the construction of high-voltage towers, replacing time-consuming manual labor.

2001 – Drones are first used for power line inspections, significantly reducing costs compared to helicopter operations.

2026 – You and your team are on stage – presenting your solution that makes replacing spacer dampers more efficient and more cost-effective.

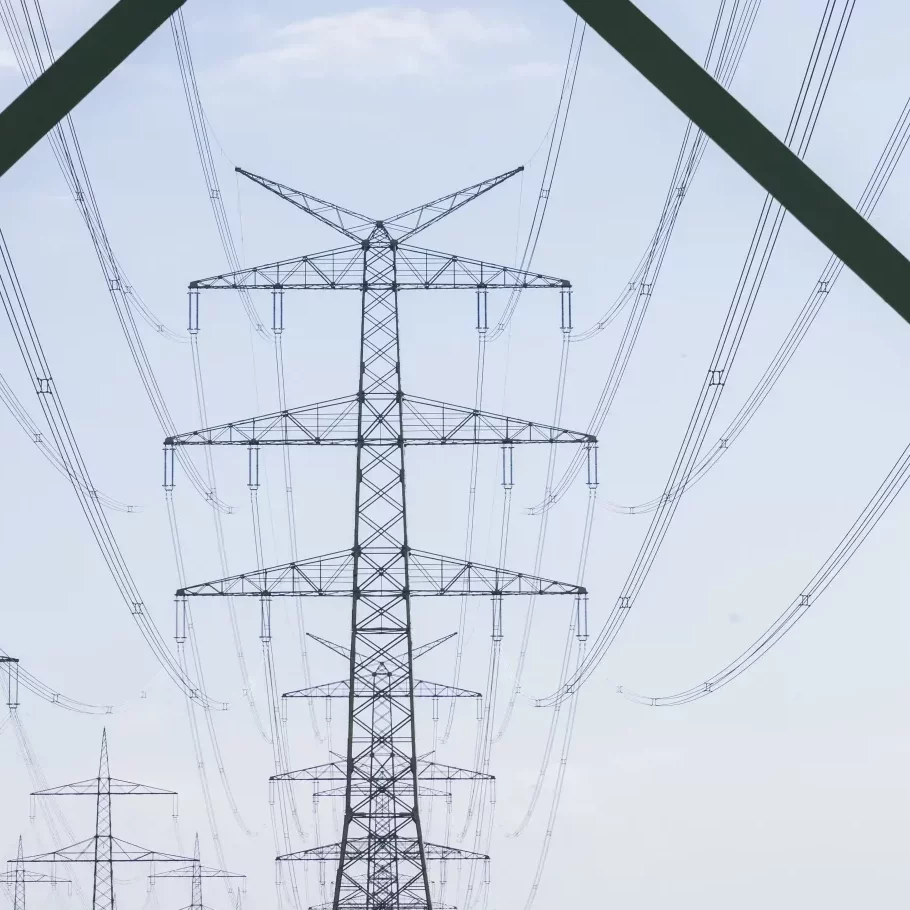

Because that’s exactly what’s possible. And exactly what’s being sought right now. Amprion – one of the four transmission system operators in Germany – ensures that electricity flows safely and reliably. A stable grid infrastructure is the foundation of the energy transition.

But even in such a critical system, there are processes that can be made faster, more ecological, and more cost-effective. Some tasks remain expensive, time-consuming, and require the utmost care – even though innovative technologies may exist that promise better solutions.

This challenge aims to address exactly that: How can we rethink the replacement of spacer dampers – and take maintenance to the next level?

No more working 30 meters up in the air, expensive helicopter flights, and complicated processes. Now is the time for innovation.

An Industry Under High Voltage

Germany’s extra-high-voltage grid spans around 36,000 kilometers – the backbone of our power supply. Amprion operates about 11,000 kilometers of it, connecting power producers and consumers from Lower Saxony to the Alps. Ensuring the safe and reliable operation of this network – and expanding it according to demand – is Amprion’s legal mandate. Within its grid area, roughly one-third of Germany’s economic output is generated.

These lines must be regularly inspected, maintained, and renewed. One of the key components: spacer dampers.

What Are Spacer Dampers?

Spacer dampers ensure that, in high-voltage lines, the individual conductors of a so-called bundled conductor (usually in pairs or groups of four) remain at a defined distance from each other. They dampen vibrations, prevent short circuits, and ensure mechanical stability. Without them: increased risk of grid faults and material wear.

Replacement and maintenance are labor-intensive – these processes are among the most expensive in grid maintenance and require special care as well as specialized expertise.

How spacer damper maintenance is typically done today:

-

Helicopter missions to reach the lines

-

Climbing specialist teams manually ascending towers and conductors

-

Use of cable cars for power lines, which require elaborate assembly

This is:

-

Cost-intensive (e.g., several thousand euros per helicopter mission)

-

Not scalable (given thousands of kilometers of lines)

-

Physically and safety demanding (handling extremely high voltages requires special precautions)

Why Robotics & Automation Are the Game Changer

What was considered a research project just a few years ago is now ready for deployment:

-

Line-inspection drones providing high-resolution real-time data

-

Gripper arms mounted on multicopters installing components without human intervention

-

Climbing robots performing bolting work on live lines

-

AI-powered systems fully automating material fatigue analysis

And the best part?

Automated systems are often cheaper than traditional methods today. They not only save on labor and downtime costs, but also reduce accident risks, response times, and emissions.

Why We’re Talking About This

Amprion has been working for years to make the power grid future-ready – continuously seeking to optimize processes. That’s exactly where we come in: bringing people and ideas together to find new approaches to concrete challenges like this one.

The Task

Even in a state-of-the-art grid, there are workflows that can still be made safer, more efficient, and more sustainable. The replacement of spacer dampers is one such case: crucial for grid stability, but still costly and complex.

That’s why Amprion, together with prototype.club, is looking for new solutions – from smarter mechanics to full automation.

👉 Find all the details about the challenge here:

“Our lines are the lifelines of society.”

– Amprion Brand Manifesto

The bottom line: We’re building the future – together

One thing is clear: solutions to optimize this process already exist – and new ideas are being developed every day. They’re just waiting to be deployed in a field that is essential for the energy supply and the energy transition.

And as we know from experience: technologies that seem niche today can become the standard tomorrow. Fifteen years ago, electric vehicles were considered a bold vision – today, they shape markets, infrastructures, and political strategies worldwide. Why shouldn’t the maintenance of our power grid change in the same way?

Now is the moment for people ready to make a difference. For those who challenge existing limits and boldly take new paths.

Stay in the loop

Which partners we’re currently working with – and how you can contribute your ideas?

Sign up for our newsletter and be the first to hear about new innovation challenges, events, and exciting startup cases.